This article originally appeared in Plastics Engineering Magazine – April 2016

Thermoplastic elastomers (TPE) are an important class of materials and are used in a wide variety of applications. In general, TPEs encompass multiple different types of polymeric material structures, and are noted for being soft and flexible like thermoset rubber, while being melt-processable and re-processable like thermoplastics.

On a basic level, thermoplastic elastomers exhibit some of the characteristics of thermoset rubber, but above their melt or softening temperatures, are melt processable like thermoplastics. This allows TPEs to be reprocessed and remolded. In the viewpoint of those familiar with thermoplastics, TPEs allow for ease of fabrication and design flexibility not afforded by thermoset rubber.

Compared with other thermoplastic materials, TPEs offer advantages in properties including:

- Softness: low hardness

- Flexibility: low modulus

- Impact strength

- Tear and abrasion resistance

- Fatigue resistance

- Desirable compression set

- Broad use-temperature range

- Chemical resistance

- Low specific gravity

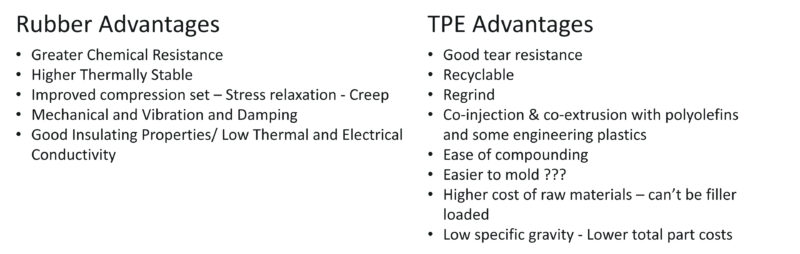

However, thermoset rubber compounds offer distinct performance advantages over TPEs due to their crosslinked structure. Absolute properties will be highly dependent on the exact compounds being compared. The advantages of TPEs are predominately in the area of processing, while thermoset rubber typically is superior in regard to performance properties, especially those related to temperature, chemical contact, and sustained stress. In all fairness, the advantages indicated in ease of compounding and ease of molding are based upon one’s viewpoint. For those familiar with working with thermoset rubber compounds, a difference of opinion may be held.

Both types of materials, thermoplastic elastomers and thermoset rubbers, are diverse classes of polymeric materials offering a wide range of properties. A comparison shows that the inherent properties are dependent on the different structures comprising the two sets of materials, as well as formulation additives. The best material for a particular application will depend on many parameters, including the design of the component and the service conditions. Designers of articles and assemblies should be well familiar with both thermoplastic elastomers and thermoset rubbers in order to choose the most appropriate material to ensure the best chance for product success.