This article originally appeared in Plastics Engineering Magazine – August 2017

The range of information that can be extracted through DMA makes it a valuable tool in the plastics analytical lab.

Dynamic mechanical analysis (DMA) can provide insightful information regarding the structure and mechanical properties of a polymeric material. However, this technique is often overlooked, and its capabilities are generally not fully understood. Because of their molecular structure, polymeric materials such as plastics have different properties compared with other materials, like metals. Specifically, these unique characteristics arise from the fact that:

- Polymers are made up of relatively long chains of repeating structural units, resulting in relatively high molecular weight.

- This chainlike arrangement results in entanglement of the individual polymer molecules.

- These polymer chains do not share chemical bonds with the other chains around them, resulting in mobility. Polymeric materials fail predominately through the disentanglement of the molecular chains.

Dynamic mechanical analysis is a thermoanalytical technique that assesses the viscoelastic properties of materials, and can provide insight into the temperature and time dependencies of polymeric materials. DMA evaluates a material’s stiffness, as measured by modulus, as a function of temperature, time, or frequency.

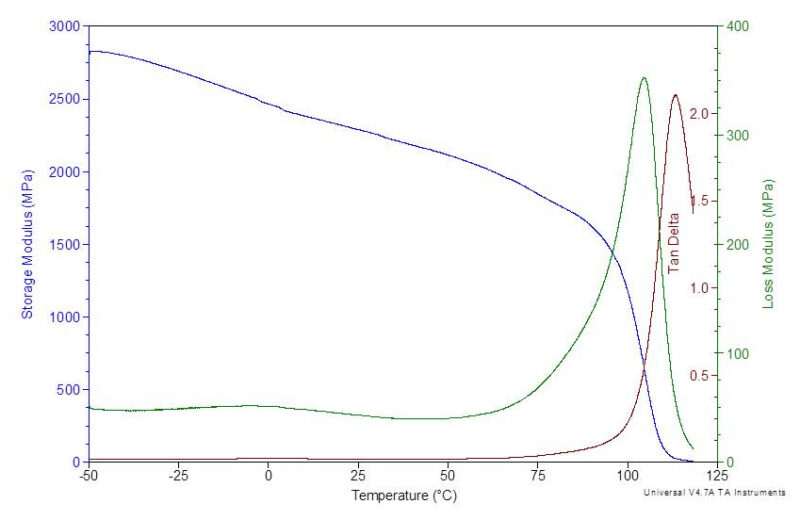

The results obtained as part of a DMA experiment include the storage or elastic modulus (E’), the loss or viscous modulus (E’’), and the tangent of the phase angle delta or tan delta (E’’/E’). As part of the analysis, a small deformation is applied to a sample in a periodic manner.

DMA thermogram of an ABS resin showing the response of

storage modulus, loss modulus, and tan delta to temperature.

For a viscoelastic material, the stress and strain will be out of phase by some quantity, the phase angle delta. A small phase angle corresponds to a highly elastic material, while a large phase angle represents a highly viscous material. The storage modulus is associated with the ability of the material to store energy (the elastic response), while the loss modulus represents the ability to dissipate energy (the viscous response).

The results of DMA experiments allow an assessment of the proportion of the elastic and viscous components within a material. DMA experiments can be conducted in several modes, including tension, shear, compression, torsion, and flexure.

This article focuses on assessing the temperature-dependent and time-dependent behavior of plastics through DMA.